This is the second of a series of what we hope you will find to be informative articles about improving operations and the guest experience by applying the principles of Operational Excellence.

Delivering Value To The Customer, Profitably

We’re all in business to make money, and the foundations are:

• our customers – the recipient of our value;

• the processes – the work and tools that deliver that value, and;

• our people – the skills, minds, and hands that perform that work

We’ll present typical situations or issues and results in each foundation, and a key tool and approach to gathering and analyzing the information and data appropriate to improvement.

The first topic was “Our Customers – the Recipient of Our Value”. If you missed it, you can find it at http://www.thecavanaghgroup.com/customers-recipient-value/

Today’s topic is the processes – the work and tools that deliver that value

All work is a process. In spite of the many arguments put forth by some folks about being “artists” or “not wanting to be constrained”, every bit of work that converts something into something else is a series of actions, each with a beginning and an end, and hopefully ultimately creating something of value.

Good processes are like well-choreographed ballet: a beauty to behold; smooth, quiet, efficient, without chaos and firefighting.

Process improvement can be driven by a wide variety of needs:

- reduced costs

- guest satisfaction

- increased capacity without a commensurate increase in costs

- faster delivery

- fewer errors, or less scrap or rework

Waste in transactional work is often hard to recognize – when something goes wrong on the plant floor, product goes down the drain or in the dumpster, somebody important has to sign off on it, and more procured. When something goes wrong in processing a payable for instance, it becomes a series of phone calls or emails initiated by the payee, and a reprint or addition to the next run, often not visible to the leaders. When a guest service goes awry, we rarely even hear about it – they just go quietly away and tell their friends…

An Operational Excellence approach is, no matter the need or desired outcome, to map and analyze the flow of the work that is being performed –first at a high level, capturing the key customers and outputs, inputs and suppliers, and a few processing steps – and then in only as much detail as necessary to identify and gather data to analyze the value, time, cost, effectiveness, and volume and flow.

This mapping and analysis can be done for any process at any level in the business – from the main (Core) process that produces and delivers the ‘thing’ or service the customer pays for, to supporting processes that represent key interactions (“Order to Cash”) to enabling processes (“Purchase to Pay”). A common first step is to quickly identify, name, and organize this process view of the business. I’ll address this in more detail in another article – first let’s get on with improving one.

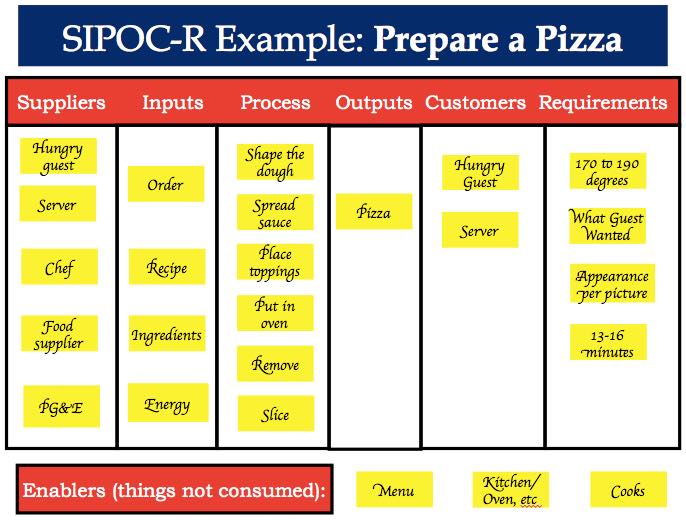

The first key tool is the SIPOC-R Map – a terrible acronym, but a great tool that yields a quick high-level view of the process identifying the alignment of the inputs to the work, and the alignment of the work with the output and customer’s needs and expectations:

We identify them in the sequence C –> O –> R –> I –> S –> P as follows:

– Customers – who ultimately gets the ‘things’ or service produced?

– Outputs – what is it we produce that each customer gets?

– Requirements – what are their needs and expectations?

– Inputs – what do we start with that is converted into the outputs?

– Suppliers – who provides those inputs?

– Process [finally!!] – what are the 5 to 8 action steps that perform that conversion? (I always like to begin this section with “what triggers this process?” [the start point], and “what’s the last thing that happens before the customer gets it?” [the stop point])

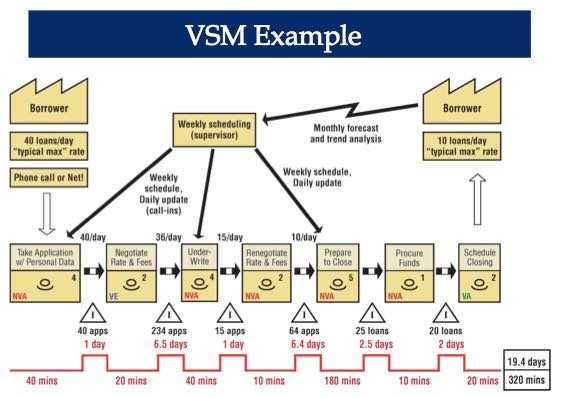

The second key tool is the Value Stream Map – a simple visual depiction of the actions surrounded by the performance data:

Value Stream Maps start with capturing the “as-is” work in a more detailed map: become the “thing” that is being transformed and follow it through the actions that are performed on it – either gather the folks together or follow each of them around and ask “and what happens next?”

This exposes:

- gaps / bad handoffs

- rework

- queues

- decision points

- batching

- redundancy (duplicate data entry is very common)

And it builds the foundation for gathering the data to analyze the value, time, cost, efficiency, effectiveness, and volume and flow.

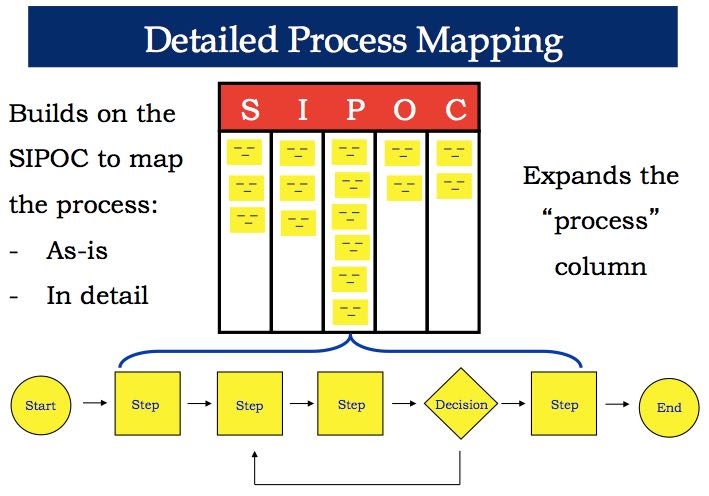

We like to add detail by expanding the SIPOC-R map:

Remember, only plunge into detail when it is worth the effort.

We think you’ll have your hands full with the “issues” that you discover once the work is made visual with the SIPOC-R and the expansion into a the detail view – the next article will discuss adding basic value stream data and analysis, and after that I’ll cover design principles of “good process”, and building a process view of your enterprise.